RokTel

RokTel Technology is a purpose designed and engineered Non-Destructive Test system developed by i2t and Custom and Contract Power Solutions Ltd (CCPS). The system is undergoing continuous development towards full automation.

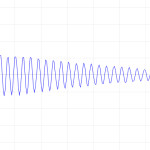

The RokTel system operates by applying an axial impact and recording the acceleration response. The response varies depending on the characteristics of the element under test.

The system is designed for use both above and below ground. RokTel is robust, portable, reliable and self-contained with an operating time of approximately 8 hours between recharge.

The RokTel system can identify the following:

- Corrosion

- Broken elements

- Reduced Encapsulation

- Unset grout/Resin

- Untensioned elements

- Excessively loaded elements

- Poor installation

- Incorrect installation (reduced bolt length)

RokTel can be used to test many different types of installations in many environments. These are used in both civil and mining applications:

- Hollow Core Bars

- Mechanically anchored bolts

- Bar Bolts 20-48mm diameter

- Twin Strand Cables

- Single Strand Cables

- Soil Nails

- Tie-Back Anchors

- Post construction Bolts

- Split Sets/Friction Bolts

RokTel can be provided as an operated service or taken on hire (training provided). i2t will provide analysis and reporting on data.

Interested parties should be:

- Mining Engineers

- Strata Control/Geotechnical Engineers

- Structural Engineers

- Asset Owners

- Suppliers

- Contractors

- Risk Managers

- Insurance providers